You are here:

- CMP Home >

- Web Exhibits >

- Stereoscopic Images >

- Manufacturing

- SUBJECT:

- COMPANY:

- GEOGRAPHIC LOCATION

Stereoscopic Images of Cleveland in 3-D

Manufacturing (Rubber, Glass, Steel, etc.)

- This gallery contains 15 slides. Click on the arrows to advance to the next or previous slide.

- Click on the the photo to see the 3-D rendering.

- To view the total effect of the 3-D versions of the images use anaglyph 3-D Glasses (red/cyan).

-

Method of Placing Material in Furnace — Plate Glass Works, Rossford, O.

Plate glass is made of pure sand, carbonate of lime, sulphate of sodam and carbon in the form of coke or coal. These materials must first be melted in pots or closed furnaces. The view here shows the method of filling the furnace from the conveyors. You will observe that the great dipperused has a long handle, so that men may stand away from the flames. The heat from the open furnace is intense. The dipper is attached to a small truck so that it can be pulled along from pail to pail. Thes pails are also suspended and fastened to a steel overhead truck directly above the furnace. As soon as the dipper is full it is pushed far back into the furnace and the material is dumped out by turning the dipper over.

After the sand and other materials are melted and changed into a pasty substance, this paste is poured on a cast-iron rolling table. The table is mounted on a truck which runs on rails so that it can be shifted from point to point in the factory. Here, on these great, smooth, sheet-iron tables, a heavy roller passes over the paste. This smoothes out the substance just as your mother rolls pie dough. These rollers weigh as mush as five tons. Just ahead of the big roller, and on either side of it, run two guards which keep the pasty glass from spreading out too widely.

The third process is that of annealing or colling the glass. The sheet of plate glass remains on the iron table where it has been rolled until it stiffens a bit. The, with two or three other sheets, it is lifted by a crane into a fire-brick kiln. Here, it rests on a floor of hot bricks. The kiln openings are built up, and the glass is cooled gradually for 3 or 4 days. The gradual cooling prevents cracking, and makes the glass tough. -

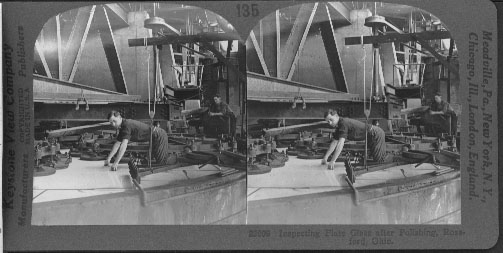

Inspecting Plate Glass after Polishing, Rossford, Ohio

After the plate glass has been rolled and properly cooled (annealed) it is taken to a cutting room where it can be shaped to a proper size.

The big plates are then moved to the polishing room. The polishing consists of three processes: grinding, smoothing and polishing. Grinding and smoothing are done almost in the same way. Rotating tables, wheels of iron such as you see are let down on the surface of the glass. Emery, fine sand, or carborundum is sprinkled on the surface. The tables of iron are let down until they fit closely against the surface of the glass and then are set in motion. The fine particles of emery, etc., cut the surface of the glass very smooth.

The next process, that of smoothing, differs from the grinding only in the fineness of the sand or emery used.

The last process is that of polishing. Revolving plates are covered with leather or some other soft material. The rubbing that the surface of the glass gets gives it a fine luster. The plates are then ready for shipping.

The United States leads every country in the world in the manufacture of glassware. The 1910 census shows that during the previous year the value of our output was $92,000,000. Our chief glass manufacturing states are New Jersey, Pennsylvania, Ohio, Indiana, and Illinois. The industry came to center in these sections because of the excellent supply of fuel. Muncie, Indiana, and other cities in that district, used their natural gas to develop their glass factories. Pennsylvania makes over one-third of the glass we produce, and the Middle Western States make another third. Belgium has the greatest plate glass factories in the world. -

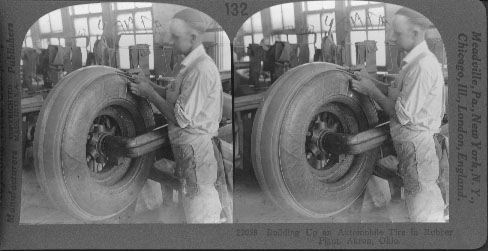

Building Up an Automobile Tire in Rubber Plant, Akron, Ohio

In the crude rubber received at the factory are sticks, dirt, bits of leaves, and beetles. These are removed by grinding the rubber in a water bath. The particles of dirt are thus washed away. The rubber is now pure enough for the first process of manufacture. The next step is to mix the rubber with chemicals. This is called compounding. In the factory here shown four or five hundred different chemicals are used to compund with rubber. Some of these are to give strength and toughness, others to give color to the rubber. It is possible to make rubber that is tougher than steel. The rubber is now ready for manufacturing purposes. What next happens to it depends on the uses to which it is to be put. For example, if it is to be made into the bandages that dentists stretch across the mouths of patients, it must be rolled very thin. This process is called sheeting. One of the greatest uses for rubber today is in the manufacture of automobile tires. You see here an automobile tire being built up. The framework of a tire is its body of fabirc or tought cloth. On an iron core, the shape of the tire, this fabric is first wound in several thicknesses. This is what the men here are doing. It is a work that demands care and skill. To become an expert workman in this department a man must have a steady hand, deft fingers, a clear eye, and good judgment. There is another way of building up tires. This is by using two crossed layers of heavy cords instead of fabric to wrap about the iron core. These cords have been filled with a rubber solution under high pressure. They are laid on the core by a machine. A tire so built up is called a Silvertown. -

![Building Up an Automobile Tire in Rubber Plant [view 2]](/stereo/graphics/22058.jpg)

Building Up an Automobile Tire in Rubber Plant, Akron, Ohio 2

The material that has been used to make up this automobile tire has passed through many machines and has been worked on by many other skilled workmen before it has reached this workman. This man is carefully trimming one of the many layers that make up this large tire. Before this tire is finished, it must be placed in a steel mould of just the right size and tread design. This mould has a metal center part which will keep the inside of the tire hollow and in shape. While in that mould the tire will be heated very hot and at the same time be subjected to great pressure. After that process the tire will go to the inspection room. There it will be thoroughly examined. Those tire that are found to be perfect will be shipped away to be sold. If any are not quite prefect, they will be marked "seconds" and sold at a lower price than the perfect ones.

You may see this very tire pass you on the road, for it is being made for one of the large, swift buses that carry passengers from one city to another.

To realize the importance of tire manufacturing you have only to remember that all automobiles must be equipped with tires, and then think of the many purposes for which automobiles are used. Perhaps you will think first of the many automobiles used for pleasure. Next remember that there is hardly a great business in the world that does not make use of automobiles. All cars used for these, and many other purposes, must have tires; therefore, tire manufacturing has become a great industry of our country. -

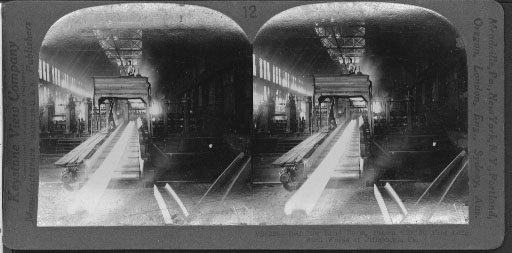

Red Hot Steel Beam, Drawn Out 90 Feet Long, Steel Works at Pittsburgh, Pa.

Pittsburgh, Pa., is the greatest steel producing city in the whole world. This picture shows a portion of the interior of one of the great steel mills. The iron is sent direct from the mine to the furnace stock pile. These are rooms in these great steel works where the iron ore and scrap iron are melted and transformed into fiery liquid. When this melted iron is drawn off it is about as thick as mild, and is called pig iron. This pig iron is the basis of all steel manufacturing. The liquid iron is then taken in huge ladles by means of electric cranes to converters or mixers. Here it is mixed with carbon of tungsten, or whatever is necessary to give the desired character to the steel. Then heavy ladles are filled with this substance and swung out over ingot moulds. The liquid steel is run into these, and freezes (way above the boiling point) into the desired shape. In the room steel rails are being made. This white, dazzling beam of metal had been rolled out to a length of about ninety feet. From this point it will be carried on rollers to a cutting platform, where it will be sawed into the proper lengths, then sent through a straightening department where the ends will be squared and the holes punched for the fishplates. It is then ready to be shipped.

The rails are loaded by a crane which is itself a huge electro-magnet. This picks up a load of steel rails as easily as a small magnet picks up a cluster of needles. -

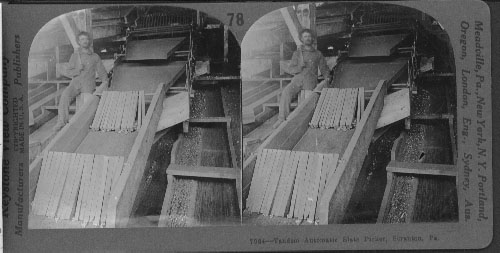

Tandem Automatic Slate Picker, Scranton, Pa.

Unless you know something of the history of coal mining, you cannot understand the value of the machine here shown. In the great breaker building the coal is first crushed. But the coal is not pure. There are minerals, especially slate, mixed with it. This must be removed before the coal is put into the cars for shipment. The labor of sorting out these pieces of slate and rock was formerly given over to boys. These were only lads of from 9 to 15 years, who sat all day long beside the small coal chute, working for a small sum of money per day. Here they sat, cramped and stooping, their little hands worn and tired, and their bodies aching.

You perhaps have heard of the term, child labor. Much has been written and said about it in the last few years. Every child should be given a chance to make the most of himself. In his youth he should be given an opportunity to learn about the things that other people do, and how they do them. Then, when he grows to manhood, he will be able to decide upon a business which he thinks he will like. The breaker boy had no chance to do this. Now laws have been passed to prevent children under a certain age, from working all day long.

Moreover, machines have been invented that make labor unnecessary in coal mining. The simple one you see here does the work of many breaker boys. As the coal slides down these chutes, the wooden jigs lift and let the lighter, fast-traveling coal pass by, but hold the heavier slate and rock. The machine is not at work, as you see it, but under each of the jigs is shown a pile of slate that had been caught. This slate is dropped into special chutes and removed from the breaker. -

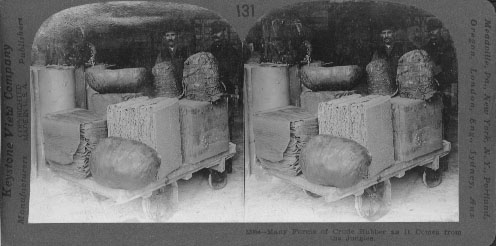

Many Forms of Crude Rubber as It Comes from the Jungle.

Forms of Crude Rubber, Akron, Ohio: This picture was taken in a great rubber goods factory in Akron, Ohio. The raw rubber you see here has come from several places in the tropics. For rubber trees grow in hot countries only, such as Brazil, Mexico, and Africa. The rubber tree is a tall, straight tree, often times 60 feet high. Its bark looks like that of the beech, and it has graceful plumes for leaves. Between the bark and the wood is a gummy fluid called latex. It is not the sap of the tree. From latex crude rubber is made. On the upper Amazon the natives go into the jungles in October to gather rubber. They tap the trees in two ways. One is by cutting the bark in a wide gash that girdles the trunk in a spiral. A trough or pail is set, and into this the latex flows from the gash. Each day the gash is extended. The other way is to tap the trees in much the same manner as sugar maples. On top of the latex so gathered a sort of cream rises. The native dips a paddle in this and holds it over a smudge of palm leaves or nuts until the latex dries. This plan he continues till he has a great ball of the size you see. The crude rubber is brought down the Amazon River in boats. Para is the chief city of the world In the export of raw rubber. In the East Indies there are many rubber plantations. There the latex is thickened by an acid, and the rubber is rolled into sheets. It is these sheets that you see on the truck. The United States imports yearly over 100,000,000 pounds of rubber. This is almost as much as Great Britain, Germany, and France combined import in the same time. Lat. 41 N.; Long. 81 W. -

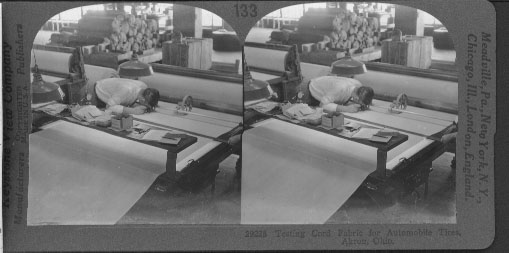

Testing Cord Fabric for Automobile Tires, Akron, Ohio

We think of automobile tires as "made of rubber." This is partly, but not wholly true. Tires are made of rubber mixed ("compounded") with other substances such as sulphur, clar, zinc oxide, carbon-black (soot from burned gas or oil), and lime, for various purposes. For rubber may be as flexible as a toy balloon or as hard as a solid tire for trucks which carry ten-ton loads.

Cotton cloth, made from long-staple cotton, is also a very important part of a tire. Heavy thread of such cotton are woven into wide sheets of cord fabric such as you see in this view. The workman in the view is inspecting the cotton fabric while it is passing over a glass table that has strong lights underneath it. He is examining the material through a magnifying glass for he must make sure it is perfect.

The cord fabric is ironed between hot rollers to make it ready for "calendering" with rubber. "Calendering" is the process that brings rubber and cotton together in one sheet. A sheet of cotton is run between heavy rollers and the rubber is pressed in between the threads of cotton so that they are like one piece of material. Many layers of such material are used in a tire.

Notice that in this view a workman is doing a very important piece of work that cannot be trusted to a machine. Machines that do wonderful things for us have been invented, but they can never take the place of a person when careful thought and judgement are needed. -

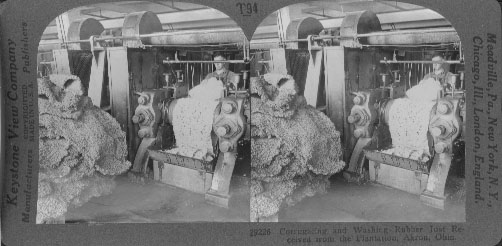

Corrugating and Washing Rubber Just Received from the Plantation, Akron, Ohio

This picture was taken in a great rubber goods factory in Akron, Ohio. The rubber is being washed by passing through great rollers over which water is flowing. Washing is the first thing done to rubber after it arrives in our factories from the tropics. The rollers also "corrugate" the rubber; that is, they press the surface into grooves and ridges. This is a sort of kneading process which breaks up particles of solid impurities in the raw rubber and thus aids materially in the washing process.

Rubber tree grow in hot countries. The tree are very tall and straight. Their bark is much like that of our beech trees. Under the bark is a gummy fluid. This fluid is called latex. From this latex, crude rubber is made. To get the latex the trees are gashed or tapped. The gummy fluid flows slowly into pails set to catch it. A pail of latex looks much like a pail of milk. Just as cream rises on milk, so rubber rises to the top of latex.

A workman builds a smoldering fire of leaves and nuts. Then he dips a paddle into the latex. Next he holds the paddle over the fire until the heat evaporates the water, leaving on his paddle a thin coating of rubber. He then dips his paddle again into the latex and again holds it over the fire. He continues doing this until his paddle has on it a thick coating of rubber. Then he cuts off the rubber and rolls it into a ball. The balls are taken to market and shipped to factories. In some countries rubber is thickened by the use of an acid.

Brazil, Ceylon, the East Indies, Africa, and Mexico all export crude rubber. Much of the rubber used in this country comes from South America. Para, Brazil, is a port noted for shipping great quantities of rubber. -

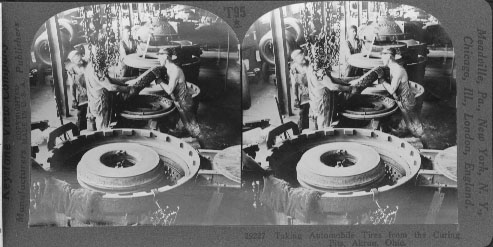

Taking Automobile Tires from the Curing Pits, Akron, Ohio

n this view the tires have just gone through the "curing" process. They are being removed from the steel forms in which they were placed for that process. "Curing" means "vulcanizing." Vulcanizing a tire means applying great heat and pressure to it. So, while in those steel forms, the tire were heated very hot and pressed very hard at the same time. The process (vulcanizing) makes the tire strong enough to stand being inflated ("blown up") by air. It also makes them strong enough to travel thousands of miles over pavements and dirt roads in all kinds of weather.

Before a method of vulcanizing rubber was discovered, our rubber goods were few and far from satisfactory. A rubber rain coat in winter became so stiff that it would stand alone. In summer the same coat became soft and stickey and stretched out of shape. Charles Goodyear, and American living in Connecticut, spent nine years in hard work and poverty trying to find a way to treat rubber so that it would not crack in winter or melt in summer. One day he threw a lump of rubber mixed with sulphur into the fire. Great was his surprise and joy to find that the fire did what he had been trying to do; it toughened the mass. Over five more years he worked to perfect his process. Without Mr. Goodyear's wonderful discovery many articles now made of vulcanized rubber would be unknown. Certainly automobile tires such as we see today would be impossible. The process of hardening rubber was called "vulcanizing" in honor of Vulcan, the Roman god of fire. -

Shooting an Oil Well with Nitroglycerin, Penna.

The word petroleum means "rock oil," or oil that comes from the ground. Far down in the earth, sometimes as far as 4,000 feert, petroleum is stored in sands which lie between layers of rock through which the oil cannot escape. We need that oil because from it are made gasoline, lubricating oils, and other products. This well has been drilled, and the driller found, by examining the dirt brought to the surface by his machine, that oil was near. The he lowered a can of nitroglycerin into the well. You know that nitroglycerin is a very powerful explosive. In the top of the can was a torpedo. A weight called a go-devil was next dropped upon the can. The torpedo exploded and ignited the nitroglycerin. A terrific explosion followed. You see the result. The oil was forced up the well and shot high into the air! That derrick is 72 feet high and the streem or oil is much higher.

This well should now yield oil for some time. If the pipe becomes clogged with paraffin, it may be torpedoed again. If such and explosion does not start a flow of oil, the dirller must either drill deeper or drill in another place.

Most petroleum is dark green in color. Some of it is thick as syrup, some is like kerosene. All crude oil must be refined before it becomes gasoline. From the storage tanks near the weeksm it is carried away in tank cars or is driven by pumps through pipes to refineries. These pipe lines are laid under rivers, through mountains, under out very feetm for hundreds of miles. In the refineries, pertoleum is heated and different products are obtained, of which the most important and valuable is gasoline. -

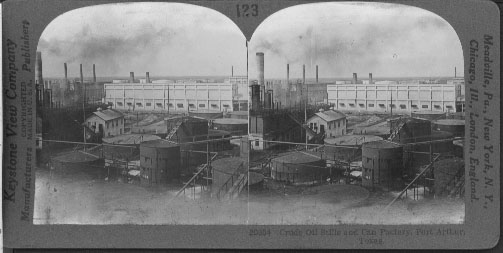

Crude Oil Stills and Can Factory, Port Arthur, Texas

Port Arthur is located on Lake Sabine, Texas, near the Gulf of Mexico. It is one of the great oil exporting ports in our country. Oil pipes connect it with the large oil-producing fields. One of these pipes is shown plainly here.

Formerly the usual method of conveying oil was in oil cars. These are large boiler-like tanks fastened on freight car trucks. This method has been largely displaced now by pipe lines. The oil fields of Pennsylvania are connected by pipe lines with New York, Philadelphia, Pittsburgh, Baltimore, and Cleveland. These have been extended to the oil fileds of Indiana and Oklahome. Now Chicago and other cities on the Great Lakes, certain cities on the eastern seasboard, and cities on the Gulf are interlinked by pipe lines. Pumping plants are located at distance apart along the line so that the flow of oil in the pipes is constantly kept up. The oil so carries from the wells is in its crude form. The large tanks that you see here are receiving stations. The oil may be taken from the tanks and refined here, ot it may be put on board oil steamers in its crude form. The large building in the background is and oil canning factory. This building receives sheet tin and makes it into cans. These cans are filled with oil, sealed, and labeled.

We are likely to forget that for the entire twnty-four hours of the day this flow of oil continues in the pipe lines. It takes thousands and thousands of wells to produce so much pertoleum. The digging or these wells keeps and army of workmen busy.

Originally petroleum was used chiefly for lighting purposes. Now it furnishes power for ships, locomotives, automobiles, and factories. -

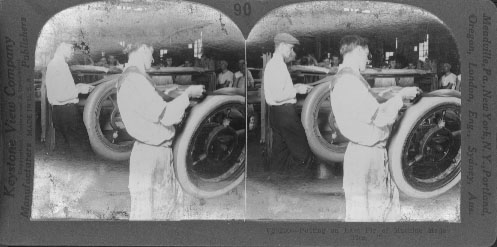

Putting on Last Ply of Machine Made Tire

In the crude rubber received at the factory are sticks, dirt, bits or leaves, and the beetles. These are removed by grinding the rubber in a water bath. The particles of dirt are thus washed away. The rubber is now pure enough for the first process of manufacture.

The next step is to mix the rubber with chemicals. This is called compounding. In the factory her shown four or five hundred different chemicals are used to compound with rubber. Some of these are to give strength and toughness, others to give color to the rubber. It is possible to make rubber that is tougher than steel. The rubber is now ready for manufacturing purposes. What next happens to it depends on the uses to which it is to be put. For example, if it is to be made into bandages that dentists stretch across the mouths of patients, it must be rolled very thin. This process is called sheeting.

One of the greatest uses for rubber today is in the manufacture of automobile tires. You see here an automobile tire being built up. The framework of a tire is its body of fabric or tough cloth. On an iron core, the shape of the tire, this fabric is first wound in several thicknesses. It is a work that demands care and skill. To become an expert workman in this department a man must have a steady hand, deft fingers, a clear eye, and good judgment.

There is another way of building up tires. This is by using two crossed layers of heavy cords instead of fabric to wrap about the iron core. These cords have been filled with a rubber solution under high pressure. They are laid on the core by a machine. A tire so built up is called a Cord. Many tire are thus built at Akron, Ohio. -

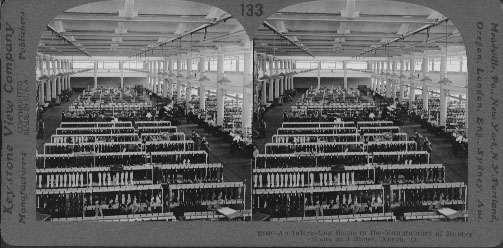

Making Rubber Boots and Shoes, Akron, OhioIn rainy weather nothing is so much needed as a raincoat and a pair of rubber boots or overshoes. In the rubber factory you see here many kinds of rubber goods are made. Raincoats are made by the thousands. Instead of cutting each coat separately, 40 or 50 pieces of fabric are cut at one time by machinery. Each coat is so cut follows the pattern to a nicety.

Then there is the boot and shoe department. This firm makes about 25,000 pairs of boots and 25,000 pairs of "rubbers" every working day. This means that here 25,000 people could be fitted out dry shod every single day. The section shown here is the boot and "rubber" department.

Boots and "rubbers" are builty up on a boot or shoe form or last. Pieces of fabric and rubber cut to the proper shape, are laid on the form. The boot or "rubber" is then vulcanized. That is, it is heated, and the rubber particles are welded together by compressed air. This makes the boot tougher than it could possibly if built up and merely dried out in ovens.

Men working here out to be able to keep healthy on account of the good lighting and ventilation. This is a good illustration of our large modern factories. This concern employers in its various departments between 18,000 and 20,000 people. Such factories make a city famous for their product. -

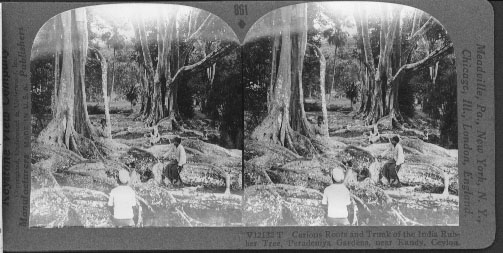

India Rubber Tree. Peradeniya Gardens, near Kandy, CeylonYou are within the wonderful 150-acre enclosure of the Royal Botnaic Gardens, four miles from Kanyd, the old Ceylonese capital. The gardens are passed on the way up from the port of Columbo, seventy miles away on the west coast.

These gigantic trees form a stately avenue near the main entrance to the park. In some parts of India rubber trees reach almost incredible dimensions - trunks 100 feet high and 75 feet in circumference, with a roof of foliage covering an area of 1600 square feet; these tree you see now are not quite so huge, for they belong to a different species, but they are big enough and queer enough to be a conspicuous feature even in this garden of tropical wonders. Notice the extraordinary shapes into which the roots have squirmed and writhed, as they reached out over the surface or the ground.

It is a near relative to these tree from whose milky juice "caoutchouc," our more familiar rubber, is procured. The Chinese have for a good many centuries known how to treat the juice to get a peculiar elastic gum for various uses, but the possibilities of the stuff were first suggested in Europe by a French traveler in South America in 1735. The enormous development of rubber manufactures in the nineteenth century led India as well as other tropical countries to contribute raw materials; large quantities are exported annually from Singapore.

These are native Singhalese whom you see sitting on the serpent-like coils of the tree roots. The costume, which includes a sort of scanty petticoat, is such as the average Columbo citizen is accustomed to wear.