You are here:

- CMP Home >

- Web Exhibits >

- Stereoscopic Images >

- Great Lakes

- SUBJECT:

- COMPANY:

- GEOGRAPHIC LOCATION

Stereoscopic Images of Cleveland in 3-D

Great Lakes (Michigan, Minnesota, etc.)

- This gallery contains 7 slides. Click on the arrows to advance to the next or previous slide.

- Click on the the photo to see the 3-D rendering.

- To view the total effect of the 3-D versions of the images use anaglyph 3-D Glasses (red/cyan).

-

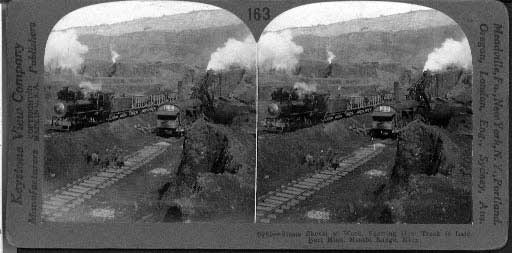

Steam Shovel at Work, Showing How Track is Laid, Burt Mine, Mesabi Range, Minn.

In many was the Mesabi Range is the most wonderful of any mountains in the world. The range is low, most of the mountains being mere hills. But a large part of these hills is made up of free iron ore. The ore, as you see, is scooped up in some places by steam shovels just as gravel is removed from pits.

In most places it is necessary to remove an overlay of several feet of clay. You can see this clay banked in the extreme background. Once the layers of ore are reached, they are removed on different levels. The steam shovel working in the foreground is cutting a trench several yards wide. The ore that it removes is dumped into ore cars that stand on tracks near by. Directly behind the steam shovel another track is being laid. As soon as the ore has been shoveled the full length of the track that is now being made, the ore cars will run on the track in the foreground.

The present Mesabi Range is the foot of an old mountain ridge worn down by glaciers. It is by far the most important iron-ore producing section in the whole world. Annually it produces almost 30,000,000 tons of ore, one-third of the supply of the world. This range, taken with Vermilion and the Cuyuna ranges, all in northern Minnesota, make the United States the leading nation of the world in the iron and steel industry. In recent years, iron smelters have sprung up in this section of Minnesota. The coal and coke needed for fuel are brought by the ore ships on their return trip from the east. But, generally speaking, it is far more profitable to take the iron ore to the coal district than to bring the coal to the iron district. -

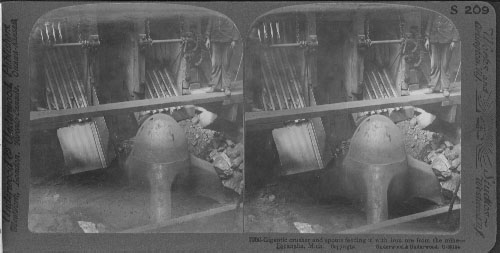

Gigantic Crusher and spouts feeding it with iron ore from the mine - Escanaba, Mich.

We are on the premises of the Oliver Iron Mining Company at Escanaba (norther Michigan). Here the ore-bearing rock taken from Michigan iron mines is crushed by this powerful machinery to get it into shape so it can be handled more easily and with greater economy of space. The economic importance of the process can be inferred from the fact that the company spends $2,000,000 just to install the plant, besides undertaking the expense of running and repairs.

Those spouts let the ore down from huge bins where it is stored when it first comes down from the mine. The crushers in this one establishment can grind yp 4,000 tons a day, ready for shipment east by Lake steamer. A considerable part of the eastern shipments go to Lake Erie ports and are then transferred to trains for the huge blast furnaces and steel mills of the Ohio Valley region (Pittsburgh, Youngstown, etc.). This giant crusher is getting raw material ready for the biggest of all America's enormous manufacturing industries.

For a sight of miners at work 140 feet below the ground, getting out iron ore, use Stereograph 7947. For the unloading of a Lake steamer, use 7970. For the melting of ore in a blast furnace, 5520. For the shaping of a 90 ft. beam of red-hot steel, 5523. -

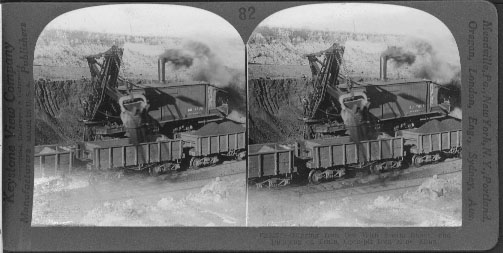

Digging Iron Ore With Steam Shovel and Dumping on Train, Open-pit Iron Mine, Minn.

OPEN-PIT IRON MINE, MINNESOTA: Iron is the most useful and most abundant of all metals. It is seldom found in its perfect natural state. It is usually combined with oxygen and other elements and found as a constituent of rocks.

Because of its iron ore, Minnesota holds an important place among the mining states of the Union. In some places the mineral is found here in almost a pure state. This picture is taken near Hibbing, in the northern part of Minnesota. It is in what is called the Lake Superior mining region, probably the largest iron producing section of the world.

Ore was first taken from it in 1884. In less than fifty years the total output of the Lake Superior mines was 192,008,000 long tons. A single mine in Minnesota has produced 1,681,000 long tons of ore in a year. The deposit is near the surface, so that mining can be carried on here on a very large scale. Sometimes the ore is dug out by steam shovels and loaded directly on the cars, as shown in this picture. A single one of these steam shovels can load two hundred cars a day, doing the work which formerly required two hundred men. Most of the ore is shipped by rail to ports on Lake Superior and Lake Michigan, great quantities going to the manufacturing centers of Pennsylvania. -

Iron Ore Being Taken from an Open Pit Mine, Hibbing, Minn.

This steam shovel is scooping up iron ore in an open-put mine in the Mesaba Range in Minnesota. This is the most valuable iron region known in the world. Most iron is hard rock and must be blasted. It must also be mined underground. But in this unusual mountain range the iron ore is so near the surface and so soft that it can be mined with steam shovels such as you see in this picture. This shovel is cutting a trench several yards wide. It is loading the ore it removes into those cars near by. This shovel can load one of those cars in about three minutes. Each year the Mesaba Range mines furnish one-third of the world's supply of iron. The Mesaba, The Vermilion, and Cuyuna Ranges, all in northern Minnesota, enable the United States to lead the world in iron and steel industries.

At one time all the iron ore from this district was shipped to the eastern coal fields. This was economical because it takes two tons of coal to smelt every ton of ore. However, instead of allowing the ore boats to return empty they were finally used to bring back coal so that some of the smelting could be done in the iron districts.

Iron and steel, which is a form of iron, are so necessary to us today that if all iron suddenly disappeared we would have to live almost as savages do. Our tools, machinery, screws, nails, ships, engines, automobiles, car tracks, frame work for large buildings, stoves, and many other things are made wholly or partly of this important and valuable metal. -

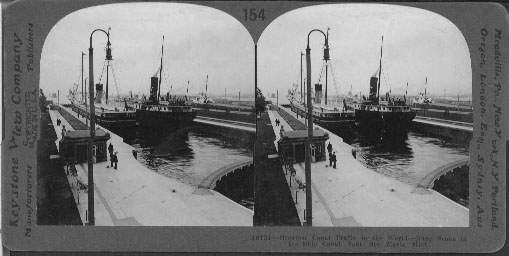

Large Iron Ore Boat Coming into Sabin Locks, Sault Ste. Marie, Mich.

The Great Lakes furnish the most remarkable inland waterway in the world. To make this waterway navigable all the way from Duluth, Minnesota, to Buffalo, New York, our country had done several things. The lake and rivers connecting Lakes Erie and Huron have been deepened. A canal has been built around the rapids in the St. Mary's River, which is between Lake Huron and Superior. This is known as the "Soo Canal." Lake Superior is twenty-three feet higher than Lake Huron, so the canal is provided with locks which lift the boats going west and lower those traveling east. This "Soo" canal handles more freight than any other canal in the world.

The odd looking "freighter" entering the locks is very well adapted to carrying ore or coal on the lakes. It is like a huge iron box with a flat bottom. There is a little house at each end. In one the crew lives. In the other is machinery. Some of these boats carry 10,000 tons of freight at one time.

What do they all carry? Many carry iron ore, which comes from the mines near Hibbing, to eastern ports. At Duluth and Superior the world's greatest elevators (store houses) are full of wheat awaiting shipment. Copper and lumber also make up many cargoes. The westward bound boats carry a greater variety of freight. Coal fills the most boats. (Why?) Others are loaded with dry goods, clothing, groceries, automoblies, machinery, and many smaller manufactured articles. -

Loading a Whaleback Ship, Chicago, Ill.

Chicago is situated in the center of the Great Central Plains, one of the most fertile and prosperous regions of the world. It is a wonderful grain producing district and has been called the "Bread Basket of the World." Most of the grain raised here and in the agricultural districts of the West is shipped to Chicago for distribution.

In this picture a cargo of grain is being loaded into a whaleback ship at one of the great grain elevators, with a comined capacity of thirty-two million bushels. Inside the tall building which we see in this view are enormous grain bins twelve feet square and eighty feet deep. The grain is drawn up into these bins by means of a series of buckets fastened to an endless belt which extends from the top of the bin to the loaded car or vessel. From these bins the grain passes through a hopper, which measures accurately, and is then sent in a continuous stream through great spouts into the back of the "Whaleback," to be transported to some port in the Great Lakes. The "Whaleback" is an extraordinary form of vessel designed especially for Lake freighters. These low, flat vessels use steam only, are without masts, and their peculiar shape, resembling the back of a whale, makes them safe in heavy storms which come up more suddenly in the Great Lakes than on the ocean. A heavy sea can wash over them without doing any damage.

The value of the grain in one of these elevators varies with the outlook for a good or poor crop - in the near future. Speculators also raise and lower the price, as is done with oil. -

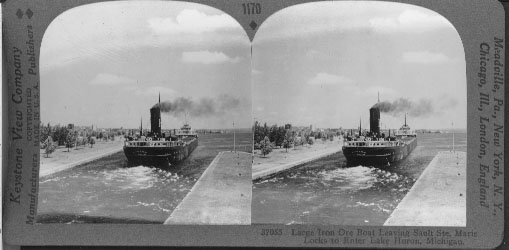

Large Iron Ore Boat Leaving Sault Ste. Marie Locks to Enter Lake Huron, Michigan

THE LOCKS AT SAULT STE. MARIE, MICHIGAN: We hear a great deal of the Suez Canal and of the Panama Canal, but there is a canal in the United States that handles more traffic than either. The Great Lakes in the United States furnish the most remarkable inland waterway in the world. To make this waterway navigable all the way from Duluth, Minnesota, to Buffalo, New York, it was necessary to do several things. The river connecting Lakes Erie and Huron had to be deepened and the connection between Lake Huron and Superior had to be negotiated in some manner.

In order to get boats through from Lake Superior to Lake Huron a canal had to be built around the rapids of St. Mary's Falls Ship Canal, popularly called the "Soo Canal." More tonnage passes through it yearly than through any canal in the world. This canal is 1 1/2 miles long and deep enough to carry the largest lake boats. One of the locks alone is 1,350 feet long and will carry boats that draw 24 1/2 feet of water.

Boats laden with iron ore from Superior, grain from Duluth, or coal from the Pittsburgh district all pass through this waterway. The odd looking freighter entering Lake Huron is well adapted to carrying ore or coal on the lakes. It is like a huge iron box with a flat bottom. There is a little house at each end. In one the crew lives. In the other is machinery. Some of these boats carry 10,000 tons of freight at one time. In 1939 more than 69,850,000 tons of freight went through the canal. The value of this tonnage was estimated to be about $1,012,829,000.